My 1800 has virtually the same cams, pistons, etc. as Alvon's. One big carb vs. two IDFs. RWHP? 104 ... exactly the same as Ace. Maybe we're both lousy builders, or maybe that's what these engines deliver in this state of tune?Daniel wrote: Your engine should have more HP then that with those cams, pistons & 40 IDFs should be

closer to 140 .

Another Dyno Day in So Cal-this Saturday

-

baltobernie

- Patron 2020

- Posts: 3466

- Joined: Sun Nov 25, 2007 6:00 pm

- Your car is a: 1973 Spider [sold]

- Location: Baltimore, MD

Re: Another Dyno Day in So Cal-this Saturday

-

Daniel

Re: Another Dyno Day in So Cal-this Saturday

Hey BernieMy 1800 has virtually the same cams, pistons, etc. as Alvon's. One big carb vs. two IDFs. RWHP? 104 ... exactly the same as Ace. Maybe we're both lousy builders, or maybe that's what these engines deliver in this state of tune?

No doesn't mean your bad builders nor was I implying that, fine tuning an engine to achieve max HP is part

Art part Science nobody can just walk up to an engine tune it to peak performance in a hour and be done if

the goal was to get every last drop of power out . There are so many variables that can effect the HP for

example lets say your using a mid 70s Fiat Exhaust manifold and Alvons running his early Manifold but every-

thing else is identical you may have the same HP at 5000 RPM but at 7000 RPM one may have more HP then the

other just on a simple difference like that !

AEM used to run a dyno tune shop in torrance California and some of the guys who worked there used to help

me a lot when i was doing things to my fiats back then (1987-91). AME is no longer in Torrance not sure where

they moved to now but have a whole line of products for the Japanese cars . I feel lucky that people like Steve

who was always helpful with information and pointers from there adventures into the dyno tuning

and engine building jobs they worked on passed that info on to me . If it wasn't for these guy sharing there tricks

and tips with me freely also another shop who used to race a 124 and Scorpion i would of wasted more money,

time on stuff that wasn't going to get me where i wanted to go !

Last edited by Daniel on Sun Oct 31, 2010 8:36 pm, edited 1 time in total.

-

baltobernie

- Patron 2020

- Posts: 3466

- Joined: Sun Nov 25, 2007 6:00 pm

- Your car is a: 1973 Spider [sold]

- Location: Baltimore, MD

Re: Another Dyno Day in So Cal-this Saturday

Certainly, I agree that obtaining the last drop of horsepower (or even the last tablespoon  ) takes a good deal of time and experimentation. I only spent about four hours on the dyno, maybe a dozen or two pulls altogether. I purchased every jet size available before my first visit, and we tried many combinations of jetting, timing, air filtration, etc. and made significant improvement over my "by ear" initial setup. The fact that Alvon got the same horsepower as I, after working on his car all year, is unlikely to be a coincidence. I'm not saying that 104RWHP is all this motor is capable of; but with similar internals, this may be the 90th percentile. I don't know where you got your 140 estimate; did you see this at AME "back in the day" using similar components?

) takes a good deal of time and experimentation. I only spent about four hours on the dyno, maybe a dozen or two pulls altogether. I purchased every jet size available before my first visit, and we tried many combinations of jetting, timing, air filtration, etc. and made significant improvement over my "by ear" initial setup. The fact that Alvon got the same horsepower as I, after working on his car all year, is unlikely to be a coincidence. I'm not saying that 104RWHP is all this motor is capable of; but with similar internals, this may be the 90th percentile. I don't know where you got your 140 estimate; did you see this at AME "back in the day" using similar components?

-

ventura ace

Re: Another Dyno Day in So Cal-this Saturday

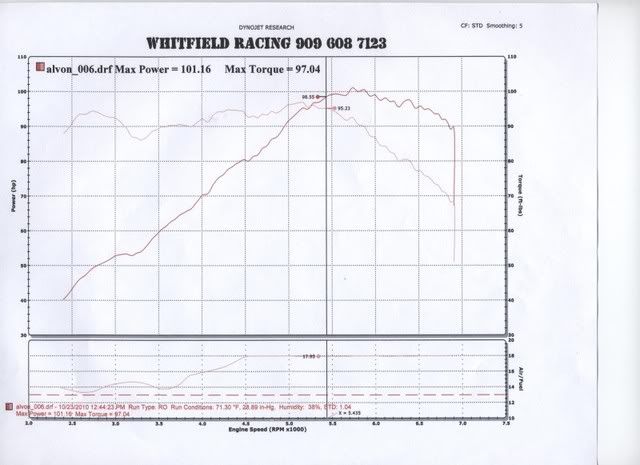

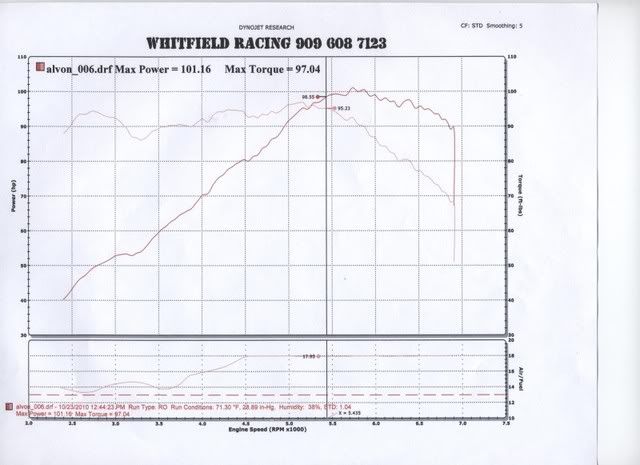

Here are traces of the dyno pulls from oct 23 on my 70 Fiat 124 spider:

Engine essentials:

1.8L block, 85 mm piston bores, total seal rings

8 mm dome pistons (15.1 cc dome intrusion, 1.2 cc valve reliefs below crown, crown flush with top of block)

Guy Croft heavy duty head gasket, 0.075" thick, 12.9 grade head bolts

2L head with 53 cc chamber volume, ported, polished, standard valves, Guy Croft triple valve springs

10.1 Compression Ratio

36-76 intake cam @ 10 - 11 thou gap (PBS B3 '40-80' regrind)

68-28 exhaust cam @ 19 - 20 thou gap (PBS S2 '70-30' regrind)

Jason Miller adjustable cam pulleys, set to 110° peak for Intake and exhaust

40 IDF carbs, 55 idles, 125 mains, 210 air correctors, 32 chokes, 0 bleedbacks, 2.0 float needles

Pierce Manifold domed filters with foam filter elements

Lightened flywheel from 1438cc engine

Cam mount dizzy with Crane 700 electronic conversion, standard coil, 28° centrifugal advance, 10° initial

Later 1608 4:2 exhaust manifold, 2:1 downpipe to 1.75" exhaust pipe, crossover to 2", no resonator, Imco Turbo performance reverse flow muffler

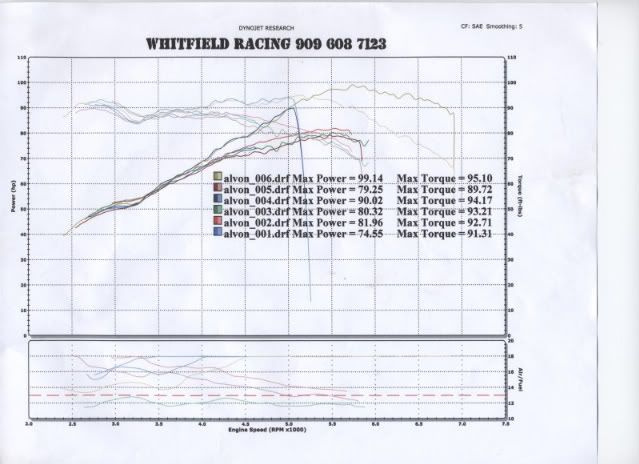

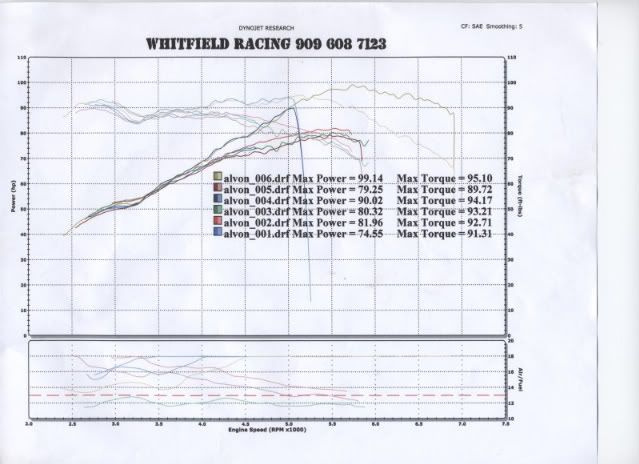

The 6 pulls were as follows:

1) Everything as described above, run was shut down at 4600 rpm due to Tech saying that engine was way too lean

2) Changed to 130 main jets, ran to 5750 rpm. Tech says engine way too lean.

3) Changed to 135 main jets, ran to 5900 rpm. Tech says engine way too lean.

4) 135 main jets, advanced timing to 15 - 18°, removed air filters, ran to 5100 rpm. Tech shut down -- too lean

5) Same as #4, with air filters installed, ran to 5800 rpm.

6) Changed intake cam to 105° peak, no air filters, Tech ran to 6900 rpm per my request, in spite of "Lean"

Plugs looked great, nice tan color. Car was spitting gas fumes out the tail pipe, in spite of Technicians sniffer reading that said A/F ratio was 18:1. There must have been a problem with the sniffer.

The best jet setting was 130 mains, based on comparing runs 1, 2, and 3. Run #5 showed a decrease in performance with advance distributor timing, and suggested that 10° was the better setting (38° total advance). No noticeable difference in performance between 110° and 105° intake cam settings (runs 4 and 6). This might suggest that the peak would be about 1/2 way between the 2, about 108°. You can definitely see where the Air filters were becoming restrictive at rpms above about 3900.

If I take the best run of the day, run #6 at 101.16 hp, and scale it up by about 3.5% supposing what it would have been with 130 main jets and 10° initial advance, we would have likely had a run of about 104 - 105 hp at the wheels, or about 127.6 engine hp if you assume 18% drive train reduction.

The previous engine build with mostly these same parts had a fair amount more pep to it at higher rpm's, probably because of a higher CR (10.6) from using a thinner standard head gasket, but there was detonation at lower rpm's that I could never get rid of. I like this combination better with the 10.1 CR. With a little improvement with the filters and maybe the velocity stacks (horns), I'll be pleased. I believe I'll check into the filters that you suggested, Daniel. Thanks for the lead.

Alvon

Engine essentials:

1.8L block, 85 mm piston bores, total seal rings

8 mm dome pistons (15.1 cc dome intrusion, 1.2 cc valve reliefs below crown, crown flush with top of block)

Guy Croft heavy duty head gasket, 0.075" thick, 12.9 grade head bolts

2L head with 53 cc chamber volume, ported, polished, standard valves, Guy Croft triple valve springs

10.1 Compression Ratio

36-76 intake cam @ 10 - 11 thou gap (PBS B3 '40-80' regrind)

68-28 exhaust cam @ 19 - 20 thou gap (PBS S2 '70-30' regrind)

Jason Miller adjustable cam pulleys, set to 110° peak for Intake and exhaust

40 IDF carbs, 55 idles, 125 mains, 210 air correctors, 32 chokes, 0 bleedbacks, 2.0 float needles

Pierce Manifold domed filters with foam filter elements

Lightened flywheel from 1438cc engine

Cam mount dizzy with Crane 700 electronic conversion, standard coil, 28° centrifugal advance, 10° initial

Later 1608 4:2 exhaust manifold, 2:1 downpipe to 1.75" exhaust pipe, crossover to 2", no resonator, Imco Turbo performance reverse flow muffler

The 6 pulls were as follows:

1) Everything as described above, run was shut down at 4600 rpm due to Tech saying that engine was way too lean

2) Changed to 130 main jets, ran to 5750 rpm. Tech says engine way too lean.

3) Changed to 135 main jets, ran to 5900 rpm. Tech says engine way too lean.

4) 135 main jets, advanced timing to 15 - 18°, removed air filters, ran to 5100 rpm. Tech shut down -- too lean

5) Same as #4, with air filters installed, ran to 5800 rpm.

6) Changed intake cam to 105° peak, no air filters, Tech ran to 6900 rpm per my request, in spite of "Lean"

Plugs looked great, nice tan color. Car was spitting gas fumes out the tail pipe, in spite of Technicians sniffer reading that said A/F ratio was 18:1. There must have been a problem with the sniffer.

The best jet setting was 130 mains, based on comparing runs 1, 2, and 3. Run #5 showed a decrease in performance with advance distributor timing, and suggested that 10° was the better setting (38° total advance). No noticeable difference in performance between 110° and 105° intake cam settings (runs 4 and 6). This might suggest that the peak would be about 1/2 way between the 2, about 108°. You can definitely see where the Air filters were becoming restrictive at rpms above about 3900.

If I take the best run of the day, run #6 at 101.16 hp, and scale it up by about 3.5% supposing what it would have been with 130 main jets and 10° initial advance, we would have likely had a run of about 104 - 105 hp at the wheels, or about 127.6 engine hp if you assume 18% drive train reduction.

The previous engine build with mostly these same parts had a fair amount more pep to it at higher rpm's, probably because of a higher CR (10.6) from using a thinner standard head gasket, but there was detonation at lower rpm's that I could never get rid of. I like this combination better with the 10.1 CR. With a little improvement with the filters and maybe the velocity stacks (horns), I'll be pleased. I believe I'll check into the filters that you suggested, Daniel. Thanks for the lead.

Alvon

-

So Cal Mark

Re: Another Dyno Day in So Cal-this Saturday

Alvon, I've got to disagree with your judgement of "way too lean" on each run. I was down at Rage today and asked him about your description of the a/f problem. He was shocked at my story and showed me each of your runs. The only run with a/f of 18 was after you removed the restrictive air cleaner.

While it's hard to see your charts, I saw them on the computer screen and most of your runs show an a/f ratio close to optimum in the 5500 rpm range. Your claim that their equipment is faulty is too harsh in my estimation.

In an effort to prevent damage to anyone's motor, they won't pound a motor that is set up that lean. It makes no sense, even on a quick pull.

It's an accepted fact that small motors don't adequately fill a large exhaust pipe at low rpms, so a/f ratio readings on any machine won't be accurate using a tail pipe sniffer. If you had an O2 bung in your header, low rpm readings would be spot on. But, above 2000 rpm even a tailpipe sniffer will give accurate readings.

There are a couple of surprises in your graphs, and if you look at the a/f graph in relation to the torque and hp readings it may give you some insight to your motors' setup.

Both hp and torque curves seem very "peaky" with a big dip in the torque curve. Look at the a/f readings at those rpms. I'm surprised at the peak hp rpm and how quickly it drops off, considering your ported head. I would expect peak hp at a higher rpm and a flatter curve on the top en

While it's hard to see your charts, I saw them on the computer screen and most of your runs show an a/f ratio close to optimum in the 5500 rpm range. Your claim that their equipment is faulty is too harsh in my estimation.

In an effort to prevent damage to anyone's motor, they won't pound a motor that is set up that lean. It makes no sense, even on a quick pull.

It's an accepted fact that small motors don't adequately fill a large exhaust pipe at low rpms, so a/f ratio readings on any machine won't be accurate using a tail pipe sniffer. If you had an O2 bung in your header, low rpm readings would be spot on. But, above 2000 rpm even a tailpipe sniffer will give accurate readings.

There are a couple of surprises in your graphs, and if you look at the a/f graph in relation to the torque and hp readings it may give you some insight to your motors' setup.

Both hp and torque curves seem very "peaky" with a big dip in the torque curve. Look at the a/f readings at those rpms. I'm surprised at the peak hp rpm and how quickly it drops off, considering your ported head. I would expect peak hp at a higher rpm and a flatter curve on the top en

-

ventura ace

Re: Another Dyno Day in So Cal-this Saturday

Mark, thanks for checking into the questionable runs for me. Yeh, I know that the charts are hard to read with all the curves on one graph. I can send them to you in a larger file that is easier to see if you like.

It was the technician that was saying that the engine was too lean, not me. I thought it was fine, or if anything, too rich. The plugs looked great. I tried to convince him that it wasn't lean, but he pointed to the 18 A/F reading and said I had to do something to make it richer or he couldn't run the equipment without damaging the engine. That's why I changed the main jets to make them richer.

The first run with the 125 jets, the A/F started around 16, climbed to 18 by 3500 rpm, and he shut it down at 4600 rpm.

The second run with the 130 jets, the A/F started at 18, then gradually fell to about 13.5 by the end of the run at 5750 rpm.

The third run with the 135 jets, the A/F started at 11.5 and stayed between 11.5 - 13.5 for the whole run.

Can this small change in jets make that much of a huge affect on the A/F ratio?

The next comparable run (with air filters in place), was again with 135 mains, and distributor advanced a bit. The A/F started at 18, and gradually worked its way down to 12 at the higher rpms.

During each of the 'warm up times' between pulls, the tech would run the engine for several minutes in the 3000 rpm range, and the A/F was typically pegged right at 18, even though we could see what looked like wet vapors coming out of the tailpipe, and smelled the gas fumes. It just plain didn't seem like it was lean to me, and my guess is that the sniffer was not properly positioned or was just not working right. The next car after mine seemed to have the same problem.

With the air filters off, the instrumentation started with readings in the 14 - 16 range and climbed to 18 by 4000 - 4500 rpm, even though the hp reading was almost 20 hp higher than the other runs. Is this possible if the engine was really too lean? it seems to me that if the A/F ratio was really that lean, it would run like crap and not get the better performance. But I don't know. I'm still learning a lot of this stuff. Am I way off base here?

It was the technician that was saying that the engine was too lean, not me. I thought it was fine, or if anything, too rich. The plugs looked great. I tried to convince him that it wasn't lean, but he pointed to the 18 A/F reading and said I had to do something to make it richer or he couldn't run the equipment without damaging the engine. That's why I changed the main jets to make them richer.

The first run with the 125 jets, the A/F started around 16, climbed to 18 by 3500 rpm, and he shut it down at 4600 rpm.

The second run with the 130 jets, the A/F started at 18, then gradually fell to about 13.5 by the end of the run at 5750 rpm.

The third run with the 135 jets, the A/F started at 11.5 and stayed between 11.5 - 13.5 for the whole run.

Can this small change in jets make that much of a huge affect on the A/F ratio?

The next comparable run (with air filters in place), was again with 135 mains, and distributor advanced a bit. The A/F started at 18, and gradually worked its way down to 12 at the higher rpms.

During each of the 'warm up times' between pulls, the tech would run the engine for several minutes in the 3000 rpm range, and the A/F was typically pegged right at 18, even though we could see what looked like wet vapors coming out of the tailpipe, and smelled the gas fumes. It just plain didn't seem like it was lean to me, and my guess is that the sniffer was not properly positioned or was just not working right. The next car after mine seemed to have the same problem.

With the air filters off, the instrumentation started with readings in the 14 - 16 range and climbed to 18 by 4000 - 4500 rpm, even though the hp reading was almost 20 hp higher than the other runs. Is this possible if the engine was really too lean? it seems to me that if the A/F ratio was really that lean, it would run like crap and not get the better performance. But I don't know. I'm still learning a lot of this stuff. Am I way off base here?

-

Daniel

Re: Another Dyno Day in So Cal-this Saturday

Bernie

I got it from doing a lot of experimenting ! but ill leave it at that for now i have a way to

help solve this ill share it later . Were only talking about 15 HP difference here i am sure

2 or 3 changes without changing any internals would get closer to the 140 mark

What exhaust and Carb are you running ?

Alvon

I agree with Mark about the Torque being a bit peaky or shall we say up and down as your engines RPM

climbs on the meter . Your Torque almost matchs the HP at higher RPMs is nice . As far as placing a bung in

your exhaust you wound need your own measuring system or might as well get one if you were going that route .

NGK and AEM sale analog wideband units for around $200 it even comes with a bung fitting you just need to

supply the hole . I'm thinking of using the AEM unit it has some cool features .

I'm thinking of using the AEM unit it has some cool features .

The one thing that stands out to me is your HP is peaking out to soon and believe there is room for more HP

at higher RPM ...

I don't know where you got your 140 estimate; did you see this at AME "back in the day"

I got it from doing a lot of experimenting ! but ill leave it at that for now i have a way to

help solve this ill share it later . Were only talking about 15 HP difference here i am sure

2 or 3 changes without changing any internals would get closer to the 140 mark

What exhaust and Carb are you running ?

Alvon

I agree with Mark about the Torque being a bit peaky or shall we say up and down as your engines RPM

climbs on the meter . Your Torque almost matchs the HP at higher RPMs is nice . As far as placing a bung in

your exhaust you wound need your own measuring system or might as well get one if you were going that route .

NGK and AEM sale analog wideband units for around $200 it even comes with a bung fitting you just need to

supply the hole .

The one thing that stands out to me is your HP is peaking out to soon and believe there is room for more HP

at higher RPM ...

-

baltobernie

- Patron 2020

- Posts: 3466

- Joined: Sun Nov 25, 2007 6:00 pm

- Your car is a: 1973 Spider [sold]

- Location: Baltimore, MD

Re: Another Dyno Day in So Cal-this Saturday

Alvon,

You got 3.90 or 4.33 gears in that thang? Going to Nashville next year?

(honey, pick up a case of Nutri-Slim ... )

)

You got 3.90 or 4.33 gears in that thang? Going to Nashville next year?

(honey, pick up a case of Nutri-Slim ...

-

ventura ace

Re: Another Dyno Day in So Cal-this Saturday

Neither, Bernie. It's the early 4.10 rear end.baltobernie wrote:Alvon,

You got 3.90 or 4.33 gears in that thang? Going to Nashville next year?

(honey, pick up a case of Nutri-Slim ...)

Nashville? Dunno. I'm planning on going through there on a bicycle at about that time, as part of a cross country cycling adventure. Or rather, a good friend is planning, and I'm hoping to participate. The schedule is to arrive in Washington DC on July 4.

Folks, 101 - 104 hp at the wheels is plenty for me. I would just get into trouble with more. I just want to understand the A/F ratio implications and optimize the carb jetting, cams, and distributor advance to get the smoothest streetable, and fuel economy with the set-up that I have for now. I will check into improving the air filters, since that should be a fairly easy change, with no down time from disassembling the engine again.

Guy Croft has suggested that I use more scrutiny on the camshafts. The reground camshafts are a compromise as compared to a proper billet cam design. Regrinds are more prone to valve spring and cam lobe damage, due to the limitations for the contact ramp and steeper accel / decel profiles with a reduced base circle to get to peak lift, and there is reduced dwell time at the wider valve opening when using regrinds. I may shop for and intake billet cam for the better performance, but I've gotten decent use out of the regrinds for the last 25,000 miles.

Alvon

-

ventura ace

Re: Another Dyno Day in So Cal-this Saturday

Yep, you did. I'm reading up on it. Your new Workshop Manual has plenty of good information to study on this topic, with lots of supporting pictures, graphs, and supporting data. I appreciate your feedback.guycroft wrote:Useless cams, Alvon!

Told ya!

G

Alvon

-

guycroft

Re: Another Dyno Day in So Cal-this Saturday

Think on this:

the standard (ie: not works spec) 124CSA had a 124 1800 motor, 9.8/1, OE 124 1800 cams, std 124 1800 big-port head with 42/36mm valves & a rather indifferent header 4-2-1 and dual 44 IDF 36mm chokes.

Factory output was 128bhp @ 6200 and 116lbf ft @5000. And it had a very full torque curve too.

Compare and contrast.

GC

the standard (ie: not works spec) 124CSA had a 124 1800 motor, 9.8/1, OE 124 1800 cams, std 124 1800 big-port head with 42/36mm valves & a rather indifferent header 4-2-1 and dual 44 IDF 36mm chokes.

Factory output was 128bhp @ 6200 and 116lbf ft @5000. And it had a very full torque curve too.

Compare and contrast.

GC

-

So Cal Mark

Re: Another Dyno Day in So Cal-this Saturday

while 104hp sounds pretty good, it's the "peaky" curve and dip in torque that would concern me. A flat torque curve makes the car very streetable and your torque curve seems to drop off at pretty low rpm. Compare the charts to some of the cars on the first dyno day. Most of them had pretty flat torque curves that peaked about 4k rpm with little drop off until over 5k rpm. Several of those cars are using our reground cams

-

ventura ace

Re: Another Dyno Day in So Cal-this Saturday

Did the results from the Dyno Tests in Aug get posted somewhere? I just saw the results offered by Lynn Shuler, and would be interested to see more.

Can you offer a guess for the cause of the dip around 3500 rpm in my car? Carburetion, Cam, Distributor advance curve, other? I believe I saw a similar dip in Bernie's torque curve from his Dyno testing a while back, but maybe not quite as pronounced. I expected to see higher torque levels of around 100 lb-ft (like Bernie's), as compared to hovering around 90 for my engine. I think both cases dropped off to around 75 ft-lbs at 6500 rpm.

Alvon

Can you offer a guess for the cause of the dip around 3500 rpm in my car? Carburetion, Cam, Distributor advance curve, other? I believe I saw a similar dip in Bernie's torque curve from his Dyno testing a while back, but maybe not quite as pronounced. I expected to see higher torque levels of around 100 lb-ft (like Bernie's), as compared to hovering around 90 for my engine. I think both cases dropped off to around 75 ft-lbs at 6500 rpm.

Alvon

-

Daniel

Re: Another Dyno Day in So Cal-this Saturday

Carburetion

To be honest Alvon your pulls aren't a good data base to start with all the runs but one were cut

short by the tech (i would of been a bit frustrated at some point dealing with that) but understand

there reasoning for being on the safe side as well . When dyno guys test engine they never push

them for more then a few seconds at a time even the finely tuned engines just play it safe and not

have something blow while there stepping on the gas pedal .

To be honest Alvon your pulls aren't a good data base to start with all the runs but one were cut

short by the tech (i would of been a bit frustrated at some point dealing with that) but understand

there reasoning for being on the safe side as well . When dyno guys test engine they never push

them for more then a few seconds at a time even the finely tuned engines just play it safe and not

have something blow while there stepping on the gas pedal .